New Products

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

RADIO CONTROL 4CH - 12/24V

Batteries not included.

General description:

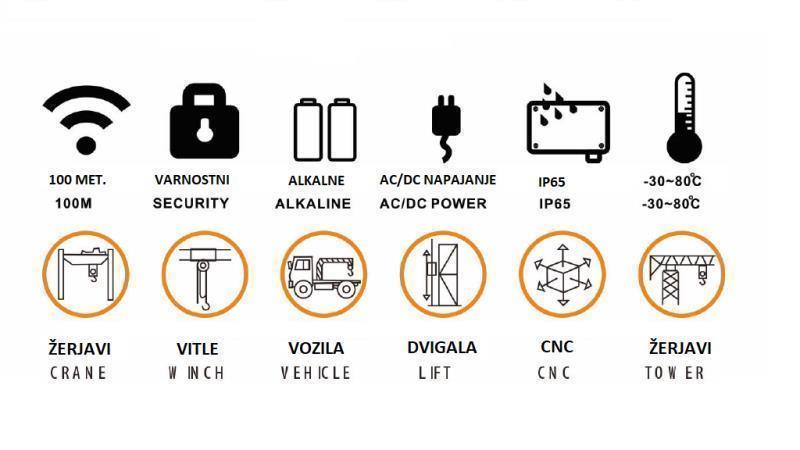

Controllers are very durable, reliable, and safe industrial radio systems for remote control. Versatile features allow their use in various remote control applications. The systems can be used for controlling factories with cranes, lifts, trolleys, construction equipment, automatic control systems, and many others.

The system includes numerous safety circuits that ensure maximum safety and ensure that the system is resistant to external interference.

The system uses advanced microprocessors with high software, where checking and correcting performance is unnecessary to ensure 100% transmission, decoding, and control of all output relays. This highly developed software includes CRC (cyclic redundancy check) and Hamming code programming (recovery).

The encoding of the transmitter and receiver decoder also uses advanced microprocessor control. The availability of 32,768 sets of unique identification codes will ensure that commands can only be executed with the appropriate transmitter control without interference from other radio systems.

For additional safety, the system also includes a special type of safety main contact relays. If the main relay fails (not opening or closing during operation), it immediately signals, and the system shuts down to prevent the possibility of any accidents occurring.

100% waterproof transmitter and receiver, housing, also space for the battery.

Remote control systems are composed of waterproof transmitters and receivers. The transmitter housing is designed using industrial strength composite materials that are resistant to dust, water, oils, acids, alkalis, heat, and sunlight, as well as resistant to deformation due to prolonged use in harsh working environments. The buttons are made from industrial strength composite materials with a minimum of one million printing cycles. To save battery energy, the transmitter is designed and manufactured with special ultra-efficiencies, requiring only two alkaline batteries for more than 150 hours of continuous operation.

Safety instructions:

Controllers are relatively simple to use, yet it is very important to observe appropriate safety, productivity, and efficiency in the workplace.

The following procedures must be observed:

- Check the transmitter housing and buttons daily for any damage that may hinder the proper functioning of the transmitter controller; any potential faults must be immediately removed from use.

- The transmitter voltage should be checked daily. If the voltage is low (red status light blinking or completely off), both alkaline batteries should be replaced.

- The red emergency stop button (EMS) should be checked at the beginning of each shift to ensure it is in good condition.

- In case of emergencies, press the EMS button (stop button), which will immediately turn off the MAIN relay receiver.

- The transmitter power switch must be turned off after each use and should never be left in the 'on' position when the unit is unattended.

- Do not use the same RF channel and identification code as any other system in use on the same site or within 900 meters distance.

- For models where a wrist strap or belt is included, it must be worn at all times during operation to prevent accidental damage to the transmitter.

- Never use a lift and equipment with two transmitters on the same RF channel and ID code.

Warning:

During the initial installation of your remote control system, a backup (second) transmitter should be tested to confirm that it operates correctly, then the batteries should be removed and the transmitter stored in a secure location. Failure to observe this safety procedure may result in unintended operation of your lift or hoist by unauthorized personnel, leading to serious bodily injury or death!

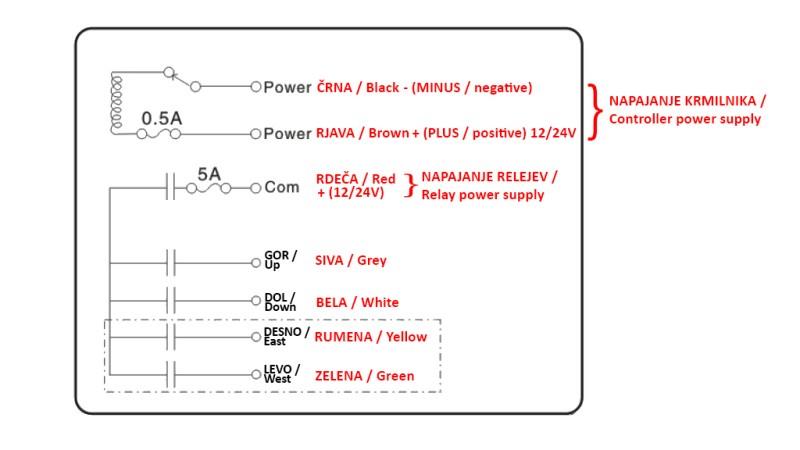

Installation details:

- Check and confirm control before installation.

- Turn off.

- Check the position of the receiver to ensure it is not affected by external factors.

- Secure the receiver firmly to prevent it from being loose or falling.

- Familiarize yourself with the power crane and emitter function settings (including relay output) to prevent incorrect connections.

- Position the receiver away from the motor, converter, and cable at least 3 m (see the next image) to avoid unnecessary interference.

- The receiver is at the top of the power space and then the output cable in the power box; do not place the receiver inside this space. If it must be in the box, then install the antenna outside the box.